|

|||||

|

|||||

|

|||||

|

|||||

|

Cautions

Thermaltake recommends the following steps to be taken before using the Pacific series radiators and water blocks:

- To ensure a clean loop, flush and rinse your radiators and water blocks with distilled water prior to use.

- Do not use tap water or distilled water as your coolant; it may harm your loop and reduce performance.

- It is strongly recommended to use market-proven pre-mix coolant, such as Thermaltake Coolant 1000. It offers great performance while protecting the entire liquid loop from corrosion.

- Before storing your water cooling components, please clean, rinse, and dry them to ensure a longer lifespan for your components.

Thermaltake recommends the following steps to be taken after completing your water loop setup:

- It is strongly recommended to use market-proven pre-mix coolant, such as Thermaltake Coolant 1000. It offers great performance while preventing corrosion in the entire cooling system – copper, brass, nickel, aluminum, and steel.

- Fill the reservoir with coolant and cycle the power on and off several times while the pump pushes the coolant into the loop.

- DO NOT let the pump run dry; turn off the power immediately if there is no liquid entering the pump.

- Fill the reservoir to the top to prevent air from entering the pump.

- If necessary, tilt the system slightly from side to side to bleed air out of the loop.

- Place some paper towels under fittings and joining points to check for leaks.

- Run the loop with the fill port open for about 24 hours to completely bleed air out of the loop.

- Before starting, flush your system correctly to prevent any coolant or unwanted particles from sticking to your tubes, radiators, and other cooling components.

- Note that coolant might fade over time.

| P/N | CL-W019-OS00TR-A |

|---|---|

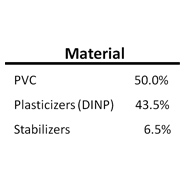

| Material | PVC |

| Inside Diameter | 1/2”(13 mm ) |

| Outside Diameter | 3/4”(19 mm) |

| Color | Transparent |